XR-based Digital Management Solution for Specialized Precision Equipment

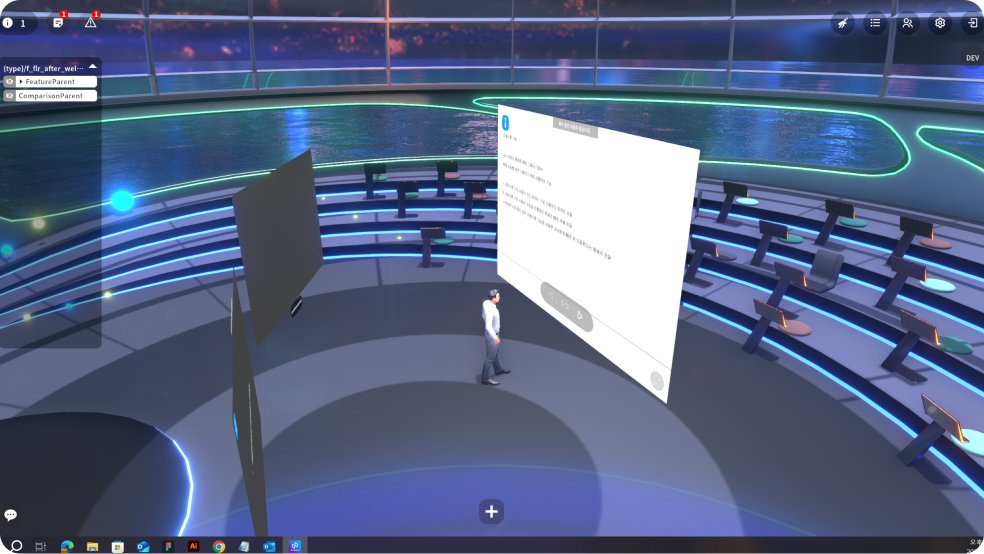

MXdts accelerates technology acquisition and utilization through training, testing, inspection, and maintenance support for precision devices across construction, aviation, defense, and medical industries.

Construction · Aviation · Defense · Medical Industries

Industrial Specialized Precision Device Management System: Mxatg

Mxatg provides education, testing, inspection, and maintenance support for precision equipment across various fields.

Functions

Monitoring

Monitoring equipment status using lightweight diagnostic tools.

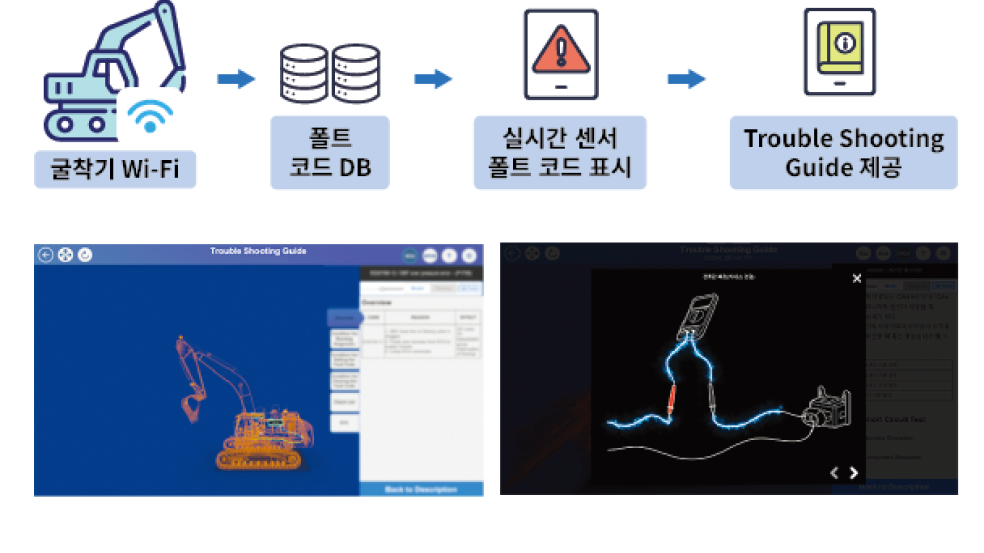

MXatg enables real-time monitoring between Wi-Fi-enabled equipment and mobile platforms.

Intuitive recognition of monitoring data

MXatg enables users to select monitoring data and manage it visually through graphs.

Monitoring data graph management

MXatg enables users to select monitoring data and manage it visually through graphs.

Functions

Guide identification and delivery

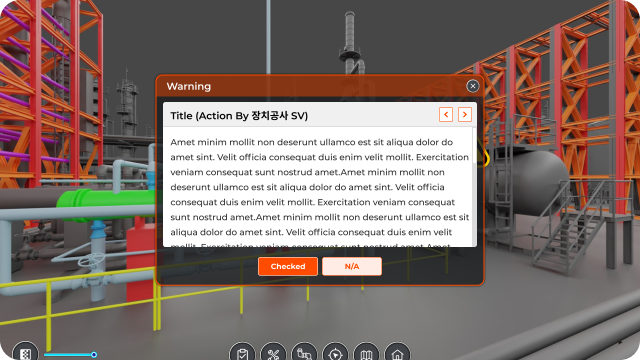

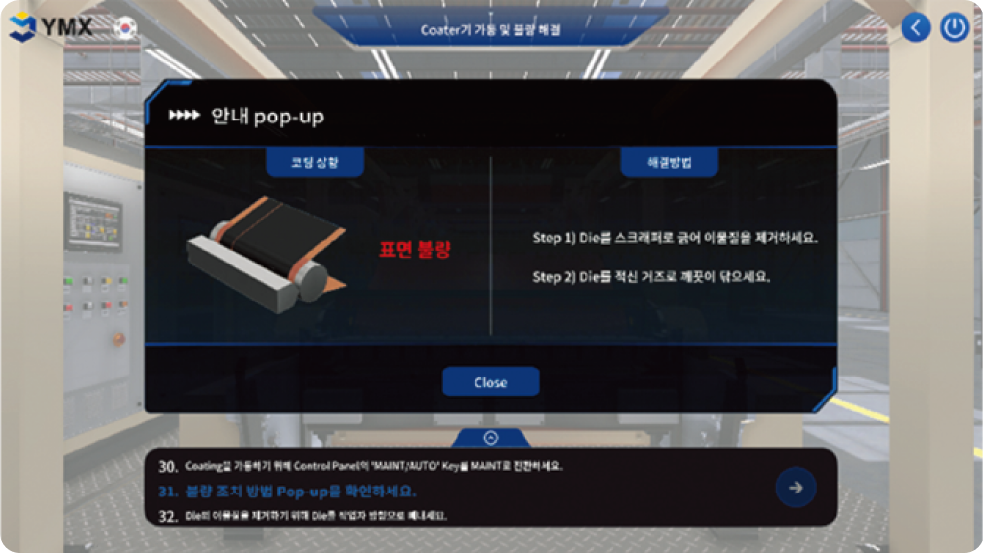

Identification of equipment failure areas and action guide

MXatg visualizes failure areas and provides troubleshooting guides using 3D AR

Matching the location of the augmented model and detecting the sensor position

MXatg enables users to match actual equipment with augmented models to identify sensor positions.

Provision of intuitive troubleshooting guides

MXatg offers video-based guides for identified failure points.

Functions

Performance testing

Management of equipment performance testing and record keeping

MXatg provides a 3D AR-based guide for testing equipment performance and enables users to measure and record the results.

Performance test guide overlay on 3D model

MXatg provides animated manuals for intuitive understanding

Measuring performance data and keeping records using measurement tools

MXatg transmits 3D AR measurement results to experts for performance data management.

Mxatg enables real-time monitoring and data management through Wi-Fi-based remote communication between equipment and mobile devices.

Mxatg provides intuitive guides for fast problem identification and resolution by matching augmented models with sensor positions.